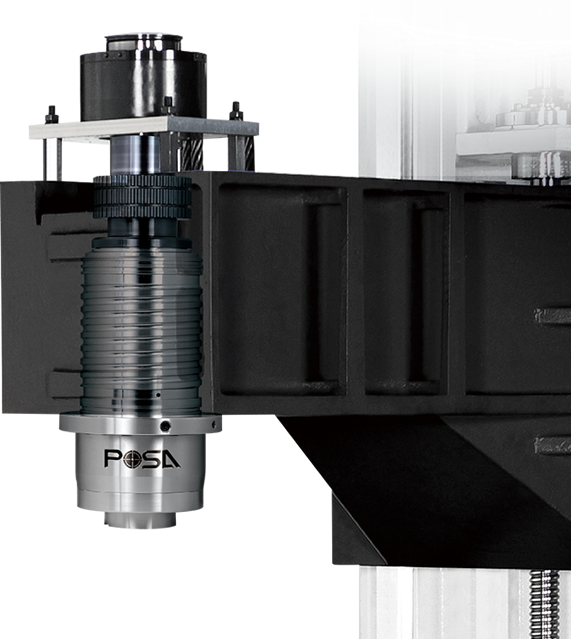

The spindle is considered to be one of the most crucial components in advanced manufacturing, where precision and reliability are not at risk. The spindle is accountable for speed, precision and sturdiness, regardless of whether you are carving high-grade aerospace alloys, or fine tuning components which require high tolerances.

Top spindle makers such as POSA are leading this specialized segment, revolutionizing the durability and performance of machines used in industrial environments.

The reason the Spindle Is the Heart of the Machine

The spindle’s quality is the most important element in every CNC machine. Imagine the spindle is the central component of any CNC lathe, or machining centre. It drives the cutting tool with great precision, stability and torque. Incorrectly aligned or poorly made spindles may lead to faulty components, however, they could also cause damage to the machine. This can reduce the lifespan of the tool and disrupt the whole production process.

Image credit: posa-spindle.com

Precision spindle technology can make a huge difference. Precision spindles aren’t produced in mass quantities that can be assembled quickly. They are meticulously engineered to be calibrated, tested, and then calibrated to perform under extreme conditions.

POSA Machinery: More Than Simply a Spindle Manufacturing Company

POSA Machine has been a leader in spindle manufacturing for decades. While many spindle makers claim to be highly precise however they are not equipped with the knowledge and engineering expertise that POSA has acquired over the years. Spindles manufactured by POSA are recognized for their rigorous in-house quality control procedures and rigorous tests. They also develop solutions that are based on performance to meet the various demands of modern industry.

POSA spindles can be found in a range of machines, ranging from horizontal and vertical machining centers to tool grinding machines. Spindles are supported by a comprehensive R&D process that is focused on functionality, but also durability over the long term, thermal stability and control of vibration.

The Evolution of the CNC Lathe Spindle

The CNC lathe spindle has witnessed significant innovation in recent years. Today’s spindles are more than just a spinning shaft. They are equipped with sensors and cooling systems along with a an intelligent balance mechanism. The POSA CNC lathe spindles are a great example that combine high-speed capabilities along with high torque and rigidity that allow machinists to handle fragile materials and hard metals, without sacrificing precision. These spindles, which are comprised of top-quality steel and advanced ceramic bearings, minimize thermal expansion, while maintaining strict tolerances during long runs. This kind of dependability translates directly into improved part quality and decreased downtime.

Customized Machining Spindles that meet the needs of the market.

There is no such thing as a one-size-fits-all machining spindle especially in industries like automotive, aerospace, and die & mold manufacturing. POSA realizes that every industry requires its own unique needs, be it spindle speed in terms of load capacity, speed, or environmental resistance. They offer customizable spindle configurations built around the specific needs of each client. When you’re designing a spinning device to be used in vertical milling or for integrating a spinning system with high-frequency into a compact machine, POSA provides the flexibility and support for engineering required by modern manufacturing companies.

More Than Machines: A Commitment To Craftsmanship

The philosophy of POSA is what separates it from other spindles. The company’s ethos is a fusion of art and ingenuity. Their design engineers work closely with clients as they listen to their needs and continually adapt their offerings to stay ahead of market trends and demands. When uptime and consistency are essential to the success of a line, choosing the right spindle partners is crucial.

Final Thoughts

The future of manufacturing rests not only on faster machines but as well on the components that are more efficient and reliable. POSA Machinery is an excellent illustration of the outcomes that can be obtained by spindle manufacturers who blend technological expertise with a concentration on customer service. It doesn’t matter if you require a powerful CNC lathe spindle, an extremely heavy-duty machine spindle, or a finely tuned precision spindle, choosing the right spindle doesn’t only matter about the details, it’s a major decision that influences everything downstream.